Carbon Neutrality

Carbon Neutrality Initiatives

Carbon Neutrality Initiatives

Zeon views climate change as a serious social issue and promotes initiatives to achieve carbon neutrality. We are implementing initiatives in energy conservation, process innovation, and energy conversion to reduce our greenhouse gas emissions, primarily at our manufacturing sites.

Our research and development efforts also contribute to society as a whole in lowering emissions through the use of Zeon products and technologies. We view weight reduction and heat management in the field of mobility as a particularly key issue and are accelerating initiatives within our specialized organizations and systems.

Contents

Energy Conversion Initiatives

Four of Zeon’s production bases in Japan (the Takaoka, Himi Futagami, Tsuruga, and Tokuyama plants) have converted to renewable energy sources for 100% of the electricity they purchase. The Takaoka Plant has begun using carbon-neutral LNG, which produces virtually no CO2 emissions. The Kawasaki Plant has introduced Carbon Offset City Gas supplied by Tokyo Gas, and Zeon has joined the Carbon Offset City Gas Buyers Alliance. The Kawasaki and Tokuyama plants reduce CO2 emissions from steam by purchasing Green Heat Certificates.

NEDO Green Innovation Fund Project—Development of Manufacturing Technology Using Carbon Recycling for Commodity Chemicals Used in Synthetic Rubber

We aim to establish two advanced technologies for producing butadiene and isoprene, which are key synthetic rubber chemicals, at high yield rates based on the recycling of carbon resources such as used tires and biomass, and to implement those technologies in society in the 2030s.

Mass Balance Approach Initiatives

Zeon has acquired ISCC PLUS certification, an international certification for sustainable products, for elastomer products manufactured at four of its production bases in Japan (the Takaoka, Kawasaki, Tokuyama, and Mizushima plants). The certification ensures that recycled, biomass, and other raw materials are properly managed throughout our global supply chain, including the manufacturing process. Obtaining the certification has enabled us to handle ISCC PLUS certified products for which sustainable raw materials are allocated through the mass balance approach.

Material Recycling Initiatives

In March 2024, Zeon completed construction of a recycling plant for cyclo olefin polymers (COP) at its Takaoka Plant. This is our first initiative to recycle our own products, and the plant will not only further differentiate Zeon’s COP products but also contribute to the realization of a sustainable society by reducing CO2 emissions.

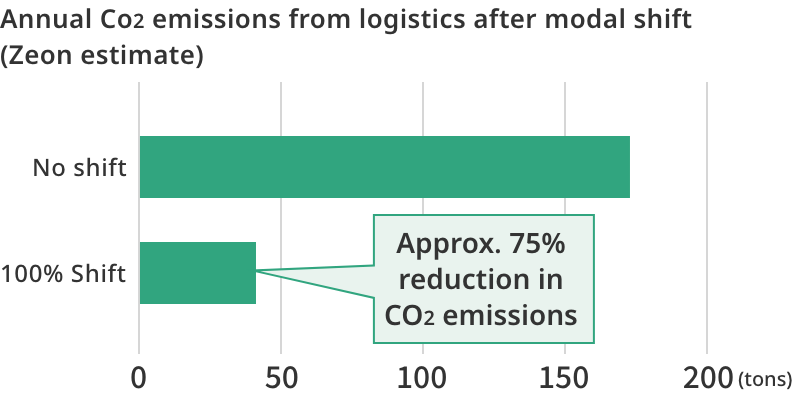

CO2 Emission Reduction Initiatives in Logistics

As a specified consigner under the revised Energy Conservation Act, we are working to rationalize the use of energy together with partner companies involved in the transportation of products and raw materials. To date, we have studied and implemented improvements in loading efficiency, modal shift to rail and ship transportation, and truck and ship fuel efficiency. An example of this is switching from truck transportation to rail transportation while containing cost increases for a portion of raw materials transportation in Japan. At present, as a result of modal shift for half of the shipped volume, we have reduced CO2 emissions by approximately 75%, according to Zeon estimates.

Related Products

Pickup